Scalable and highly efficient powertrain technology platform

Leadership: Valeo

Contributing: AVL List, Brno University of Technology, Mercedes Benz AG, Infineon Technologies AG, Technische Universität Dresden

Objectives

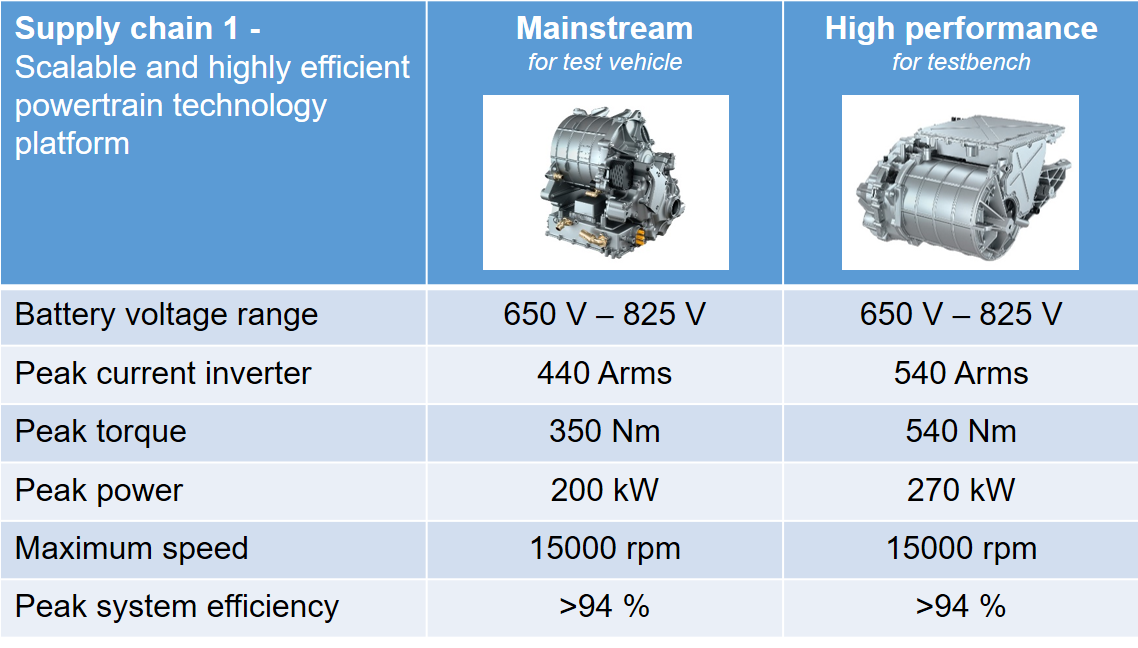

- Development of a scalable 800 V powertrain technology platform including inverter, motor and gearbox with the following parameters:

- Continuous power: 40 kW – 120 kW

- Continuous torque: 1100 N.m – 2700 N.m (at wheel)

- Maximum RPM: 16000 (motor)

- Peak RMS current of the inverter: 300 Arms – 600 Arms

- Operating voltage range: 450 V – 920 V

- Use of SiC power semiconductors in the inverter

- Assembling and test of the developed 800 V inverter with motor and transmission

Description

This supply chain is the heart of the 1000kmPLUS project, since it will provide a scalable and highly efficient powertrain technology platform, which includes a scalable and modular design for the inverter-motor-gearbox block. The common integration of these three elements enables economies of scale in mass production, thus enabling a cost reduction of at least 20% for future electric powertrains. Thanks to this technology platform, more affordable electric powertrains independent from the vehicle brand will be offered by European companies to the automotive market. To demonstrate this capability, the outcome of this supply chain will be an automotive powertrain consisting of a 800 V three phase permanent magnet synchronous motor, a 800 V voltage source inverter based on SiC-MOSFET power modules and a transmission with a single-speed gearbox. To demonstrate capability of the developed powertrain technology platform, the outcome of this supply chain provided by Valeo will be a tested 800 V powertrain prototype offering a continuous power of up to 120 kW and continuous torque of up to 2700 Nm, ready to be integrated in the demonstration vehicle in SC3. The development of the 800 V powertrain technology platform is based on an existing series development done for 400 V DC-link voltage. Power scaling at 400 V is done by using different Si-IGBT power modules and by increasing the number of output phases from 3 to 6 at a certain power level. The increase from 3 to 6 output phases is necessary due to the output current limitations of available Si-IGBT power modules. The target in the 1000kmPLUS project is to achieve the same performance characteristics with reduced currents at an 800 V DC-link voltage. At 800 V, the needed current output for the same powertrain power is roughly halved and scaling can be done by only using different semiconductor technologies (Si-IGBTs and SiC-MOSFETs) and chip area. It is not necessary anymore to increase the number of motor phases, which results in an easier and much more cost-effective scalability of the motor, as the winding system remains at 3 phases for all power levels and only length and diameter is scaled. This is the enabler for a simple and cost-efficient scalability of power in OEM’s vehicle platforms. The main technical target data is summarized in the following table:

Since a long driving range is one of the key parameters when considering the adoption of an electric vehicle by a customer, the focus will be on SiC-based inverters due to their superior efficiency. Besides efficiency improvements, the use of 800 V SiC-technology is the enabler for strong additional benefits summarized below:

- Reduced motor losses: Due to higher PWM-frequencies, the harmonics and the associated losses in the motor can be reduced.

- Less weight & volume on vehicle level: The inverter volume can be decreased thanks to the reduced cur-rents at 800V and by decreasing the mandatory DC-link capacitor when using higher PWM-frequencies. Cables and busbar connections are also smaller thanks to the lower currents.

- Improved acoustic behaviour: The switching frequency of the inverter can be set above the audible range, so audible emissions are reduced significantly. With advanced switching methods, the noise, vibration and behaviour can be actively controlled.

- Driving range extension: The improved efficiency allows for 4-12% more electrical driving range with the same energy stored in the battery installed in the vehicle.

- Scalable “Cost@power”: all power classes can be equipped with 3-phase inverters and motors. Power scaling is then just done by changing motor length and/or diameter.

- Fast charging: 800 V battery voltage enables fast charging at 50 kW, 150 kW and up to 350 kW.