Fast charging capable and weight optimized battery system

Leadership: Fraunhofer IISB

Contributing: AVL List, Mercedes Benz AG, Technische Universität Dresden, Valeo

Objectives

- Optimization of automotive grade battery cells to enable ultra-fast charging capability (up to 350 kW charg-ing power at pack level)

- Adaption of an existing open-source BMS solution to the requirements of the battery and demonstration ve-hicle

- Development, assembly and test of the fast charging capable battery system of around 100 kWh at 800 V and less than 600 kg

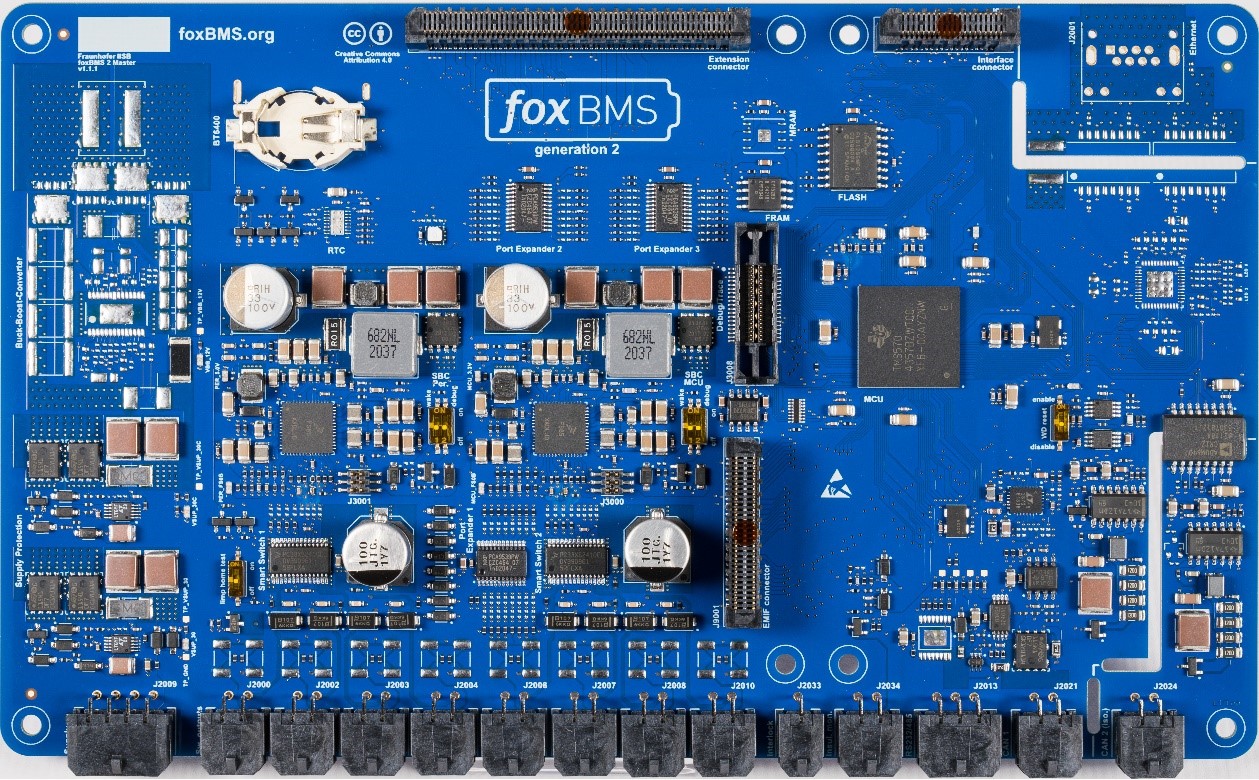

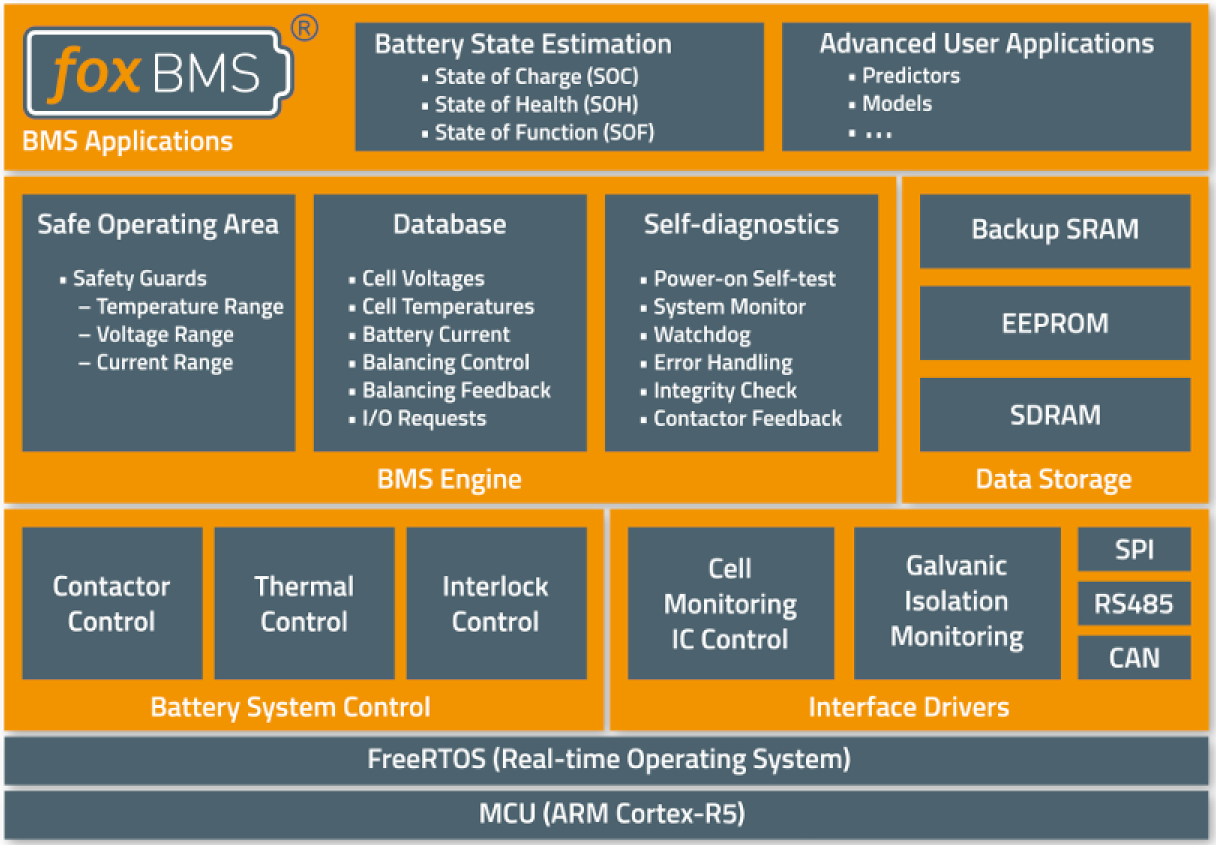

The battery management system that will be used in the 1000kmPLUS project will be based on the existing foxBMS 2 platform. foxBMS 2 is the second generation of the modular and open-source Battery Management System (BMS) development platform from Fraunhofer IISB. The foxBMS platform is a free, open and flexible development environment for the design of complex and highly demanding battery management systems for mobile and stationary applications initially released in 2016. It is worldwide the first universal BMS platform providing open source for both hardware and software, and is able to manage modern energy storage systems. The architecture of foxBMS is the result of more than 15 years of development in innovative hardware and software solutions for lithi-um-ion battery systems. The foxBMS hardware and software building blocks are used successfully in battery electric vehicles based on lith-ium-ion NMC/Graphite battery cells, where it has obtained a road homologation by TÜV Süd in Germany.

The hardware of foxBMS enables the management of high-performance prototypes of complex lithium-ion battery systems of any size (i.e., from one cell up to several hundreds of cells). The redundant hardware architecture of foxBMS is well suited to develop battery systems requiring a high level of safety and availability. The hardware is licensed under the Creative Commons Attribution 4.0 International (CC BY 4.0) license. The BMS consists of the BMS-Master board on which the software is running on two separated microcontrollers. The BMS-Master is connected over the BMS-Interface in a daisy-chain architecture to the BMS-Slaves, which are measuring the cell voltages and cell temperatures in each battery module. The BMS-Master controls all the components in the battery junction box (BJB), like the power contactors, current sensor, interlock, and the galvanic isolation monitoring.

The software implemented in foxBMS uses only specifically developed open source and free of charge software components, or free of charge third-party software. The entire source code of foxBMS is provided online on GitHub and includes its own development environment and configuration files, thus enabling immediate use on Windows and Linux operating systems. The software is licensed under the BSD 3-Clause license. All foxBMS parts can therefore be utilized unrestrictedly, including free and open-source use, as well as closed source commercial use.

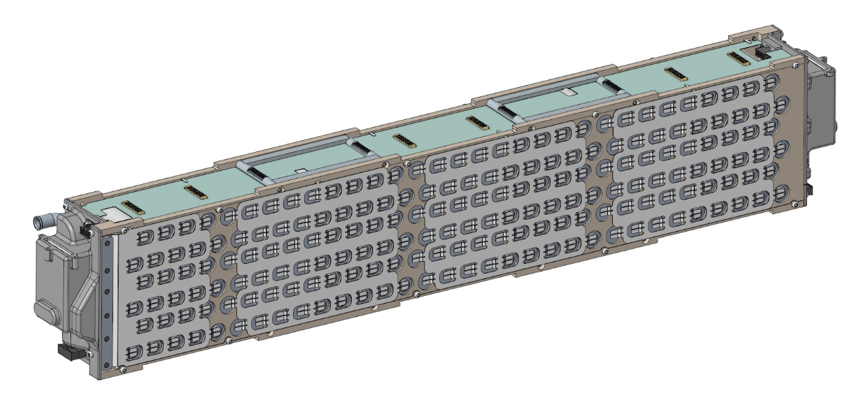

The 800 V battery system will provide around 100 kWh of energy with a total weight of less than 600 kg. It will be designed with a liquid cooling system consisting of bended flattubes fitting the shape of the cylindrical 21700 type cells. The battery cells will be assembled into battery modules, which will also contain the BMS-Slaves electronics to monitor the cell voltages and the temperatures, and to perform the cell balancing. The battery modules will be assembled in a battery pack and connected to the BJB to become the battery system. The housing of the battery system will be optimized on lightweight by TUD.

Once assembled, the battery system will be tested electrically and thermally, especially at high charging rates, to ensure proper operation before it will be integrated into the demonstration vehicle in SC3.